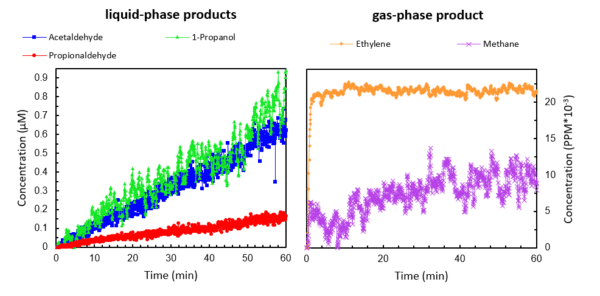

Figure 1. Real-time data collection using SIFT-MS analysis: Aldehydes and other small compounds being generated and monitored as part of the reaction process.

Combating the accumulation of carbon dioxide (CO2) in our atmosphere is one of the critical challenges facing scientists today. One promising approach to mitigate CO2 levels in waste exhaust is by electrocatalytic CO2 reduction (ECO2R), which converts CO2 into up to 16 useful products including hydrocarbons, alcohols, aldehydes and ketones. The challenge? Rapid screening of ECO2R catalysts relies on measuring all these products in the presence of high levels of CO2.

This complex analytical task cannot be adequately addressed by conventional techniques. Online GC/MS, for example, only reports on the gaseous products of ECO2R every 10 – 20 minutes and a separate analysis is required for the liquid phase products.

In their search for a more suitable tool, researchers at the National University of Singapore (NUS), led by Dr. Peter Lobaccaro (pictured), identified SIFT-MS as a viable candidate. SIFT-MS has already been used for the real-time detection of chemicals relevant to ECO2R and it can be applied to the direct analysis of trace compounds in the reaction’s CO2 exhaust stream. It is also highly sensitive, enabling it to measure the vapor concentration of liquid products in the exhaust stream, which can be correlated to the liquid-phase concentration in the reaction vessel without the need for a separate measurement.

A robust real-time technique would greatly reduce the time required to identify viable catalysts: from days to a few hours

The team began by identifying unique product-ion signals generated when their target compounds (10 in total) were ionized using the SIFT-MS reagent ions (H3O+, NO+ and O2+).

An external calibration was performed to determine the SIFT-MS response to standards of these compounds when sampled directly from an ECO2R reactor under typical experimental conditions. For liquid-phase analytes, a standard solution was spiked into the reactor and measured in the effluent gas as CO2 was bubbled through. With this framework in place, it was then possible to observe the real-time formation of products in a genuine ECO2R experiment. Both gas- and liquid-phase products were quantifiable in real time for a 60-minute period, as shown in Figure 1 above. This remarkable real-time information confirms that the liquid products accumulate gradually in comparison to the steady-state release of ethylene and methane.

In demonstrating the suitability of SIFT-MS for monitoring the outputs of an ECO2R reaction system, the team at NUS have given researchers a significant boost in the race to resolve our greenhouse gas crisis.

Initial Application of Selected-Ion Flow-Tube Mass Spectrometry to Real-Time Product Detection in Electrochemical CO2 Reduction” can be found on the publisher’s website here.

In collaboration with the National University of Singapore (NUS), led by Dr. Peter Lobaccaro (Research Fellow of NUS Nanoscience & Nanotechnology Initiative / Oak Ridge Associated Universities Fellow at the U.S. Dept. of Energy Solar Energy Technologies Office D.C., USA)