Public emissions of unpleasant odors are as embarrassing for industrial facilities as they are for individual people. Analyzing industrial odor presents a challenge to some laboratory techniques, due to the chemical diversity of odor compounds, low human odor thresholds and the dynamic nature of the odors themselves. Fortunately for the operators at Gelita, a gelatin manufacturing plant in Christchurch, New Zealand, SIFT-MS has been successfully deployed to meet these challenges.

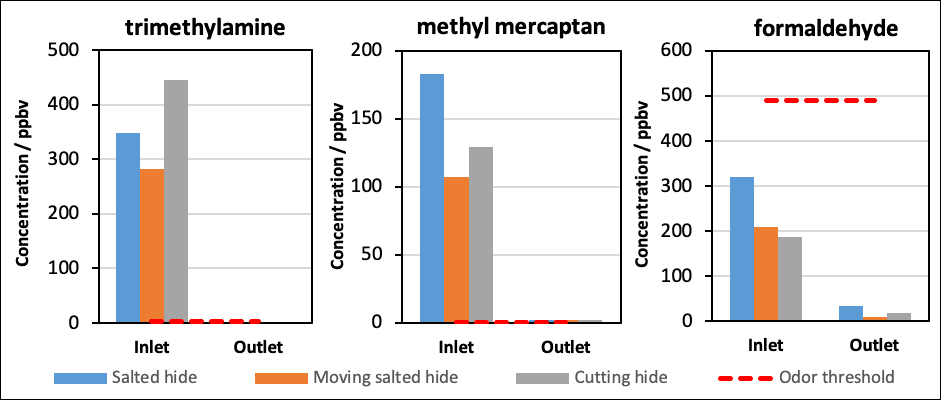

Gelatin production uses various chemical processes to extract collagen from animal hides, producing pungent odors that can be released into the surrounding property, prompting complaints from neighbors. To mitigate this, Gelita evaluated the odor-eliminating photoionization technology of Neutralox®. By using SIFT-MS, key malodor VOCs (ammonia, trimethylamine, methyl mercaptan, ethyl mercaptan, carbon disulfide, ethanol, formaldehyde and acetic acid) could be quantified both at the source (inlet air) and after passing through the Neutralox® air deodorizer (outlet air). The figure below shows the reported concentrations recorded for trimethylamine, methyl mercaptan and formaldehyde in the hide shed of the Gelita factory during different processes (salting the hide, moving the salted hide and cutting the hide). The photoionization device was shown to reduce the concentrations of odorants to below the odor threshold, reducing the risk of unfavorable emissions in the future.

The ability of SIFT-MS to directly quantify these chemically diverse odorants within a single scan, at a sensitivity below the human odor threshold, made this evaluation possible. Not only that, the Voice200ultra SIFT-MS unit did not object to sampling these objectionable odors.